Industrial research on the effect of printing inks on the recyclability of plastic films

Demand for premium recyclates is high for all packaging formats. A key reason for this is that retailers and all major brand owners have now geared their sustainability strategies towards reducing greenhouse gas emissions, protecting ecosystems, using resources with foresight, promoting the circular economy and increasingly replacing primary materials with secondary ones.

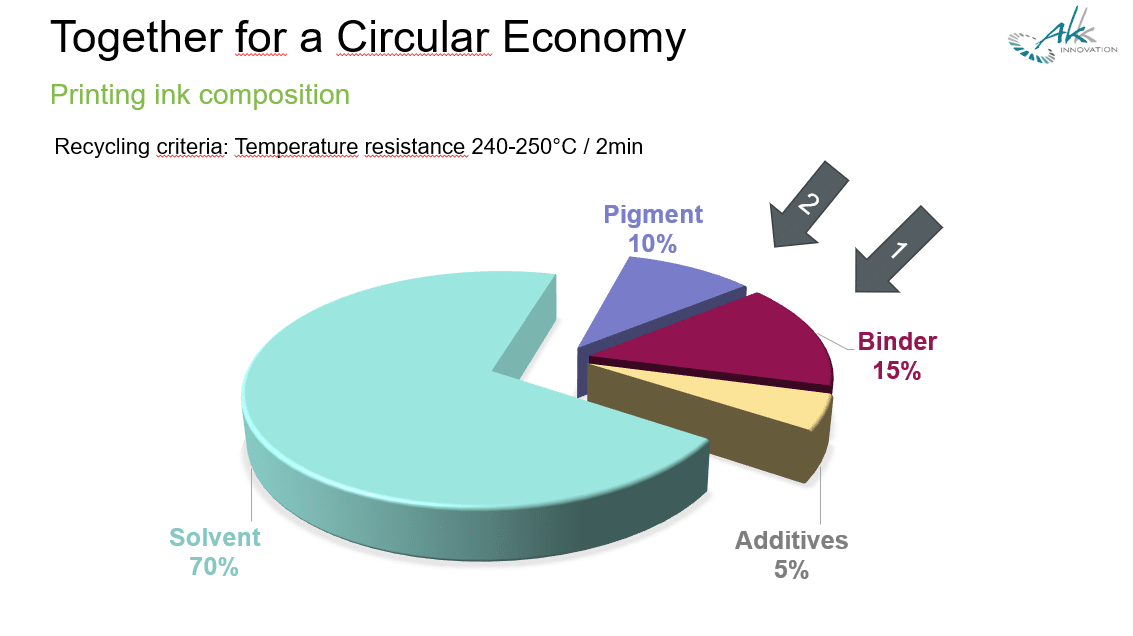

The inks used in film and package printing have a significant influence on the quality of recyclates and the recycling process – and thus on the expansion of a plastics circular economy in the packaging sector. Currently, there are different specifications for the quantity and properties of printing inks. Therefore it is a challenge for all manufacturers to design fully recyclable printed packaging such as pouches, tubes, cups or trays.

The PrintCYC Initiative

The PrintCYC initiative has been established as an industry consortium in 2019 to investigate fully printed, polyolefin-based packaging films in terms of Circular Economy and to introduce new solutions for these plastic packaging materials. Members of the initiative are machine suppliers Brückner Maschinenbau, Kiefel and

PackSys Global, Profol, a specialist for PP cast films, the printing ink manufacturer

hubergroup Print Solutions, and Erema, a specialist in recycling technology. The initiative was coordinated and co-initiated by Dr Annett Kaeding-Koppers, an independent expert and consultant for the development of sustainable packaging solutions. As part of the project work, printed films including the ink components, were examined with regard to their recyclability and recyclate quality.

NC-based inks

The focus of PrintCYC was to process printed packaging films and to test the quality that can be achieved in mechanical recycling without deinking. The recyclate quality was then evaluated chemically-analytically and physically-technologically.

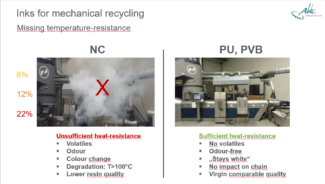

In the first step, the influence of the binding agent of the printing inks used was analysed. Nitrocellulose (NC), the most widely used binding agent today, proved to be less suitable for the mechanical recycling process due to its limited temperature resistance. Furthermore, strong, respiratory irritating outgassing as well as an unpleasant odour and a colour change of the recyclates were observed. Therefore, it is recommended to remove NC-based inks before mechanical recycling. Otherwise, the reuse possibilities of the recyclates are significantly limited.

PU binding agents and mechanical recycling

The thermostable binder PU (polyurethane), on the other hand, proved to be the best solution for mechanical recycling without deinking as no harmful outgassing, strong odours or colour changes were detected. The recyclates could be processed on laboratory extrusion lines to cast films made of 100% recyclate without any problems and could be biaxially stretched on a laboratory stretching frame like virgin material.

Recyclability of white, yellow and red pigments

As another component of printing inks, some selected inorganic and organic pigments were tested. The inorganic white pigment TiO2 proved to be temperature stable and passed through the recycling process unaltered. Organic Azo pigments, such as most standard red and yellow pigments, are more temperature sensitive and were therefore investigated in more detail. The initiative considered the pigments yellow (Pigment Yellow 17) and red (Pigment Red 57:1) as commercially available standard pigments for flexo and gravure printing and integrated them into a test print image for flexible packaging. Both pigment types showed good recyclability and resulted in odourless and optically flawless, colour-stable PP recyclates. These could be used as a colouring masterbatch for cast films in the same way as virgin material. Thus, the use of standard pigments in recyclable packaging seems possible. However, this still needs to be investigated in more detail.

In addition, the PrintCYC initiative had the recyclates analysed by the Swiss quality testing laboratory SQTS. The laboratory carried out a specific migration screening test to ensure that the recyclates comply with the limits of Commission Regulation (EU) No. 10/2011 and the Swiss Commodities Ordinance 817.023.21 on food contact materials and articles. The positive results open up a wide range of possibilities for reuse in various film and packaging applications. However, the use in food packaging must be examined on a case-by-case basis with regard to the specific legal requirements for recyclate reuse. The selection of recycling-friendly ink compositions may contribute significantly to improve the quality of recycled materials and also determines the use of washing processes.

This means that printing inks are crucial for recycling, especially for film packaging. However, they are not yet sufficiently described in the existing guidelines. Likewise, there is a lack of further practical examples with different printing (printing inks, pigments, frontal printing, interlayer printing, full-surface, partial-surface printing), to generate further insights and opportunities in and for the supply chains.